wye delta starter troubleshooting

The compressor unloaded 66 on startup through internal unloaders. When the start command is issued contactor 1M is closed connecting the motor in a Wye configuration.

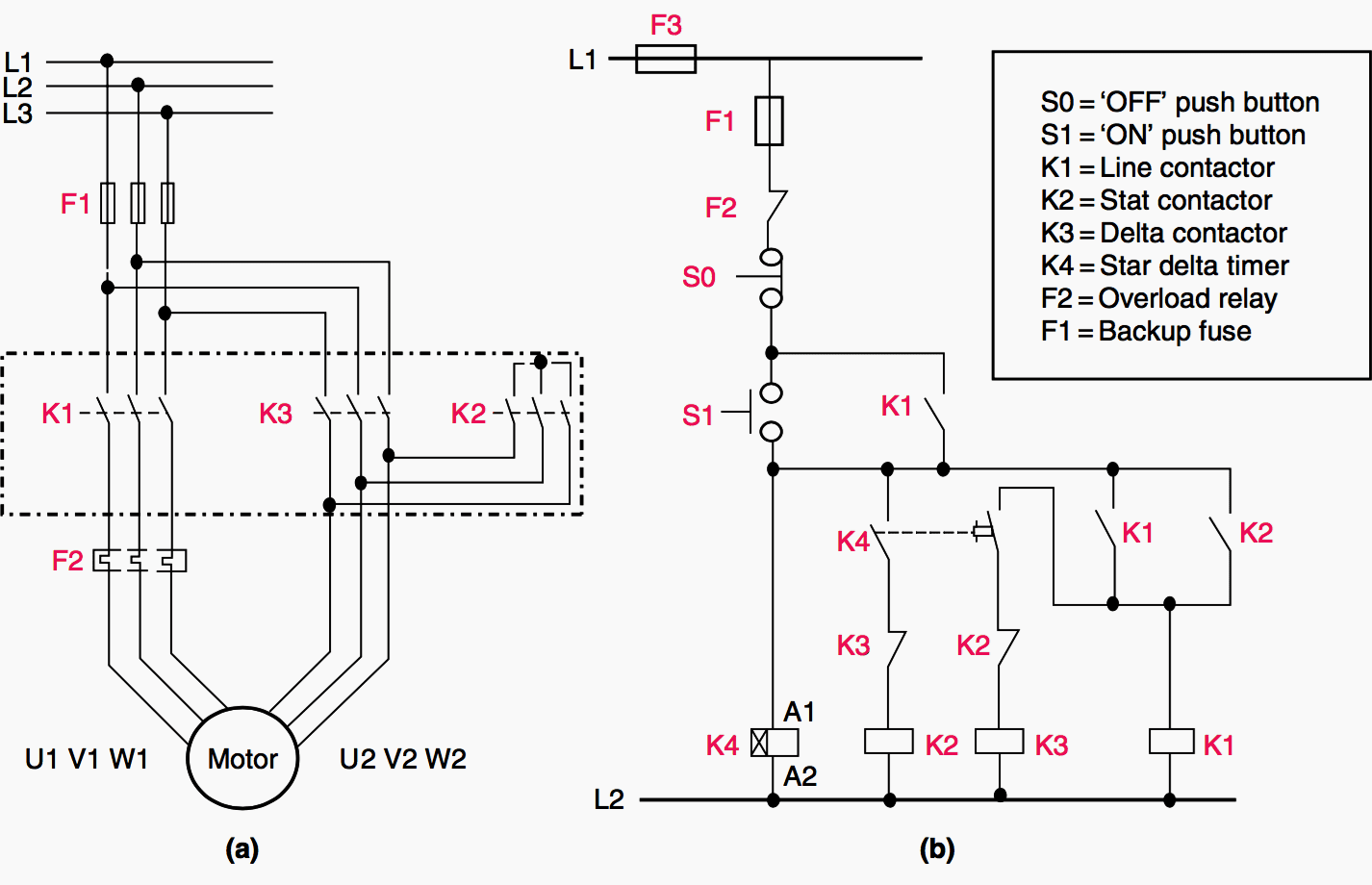

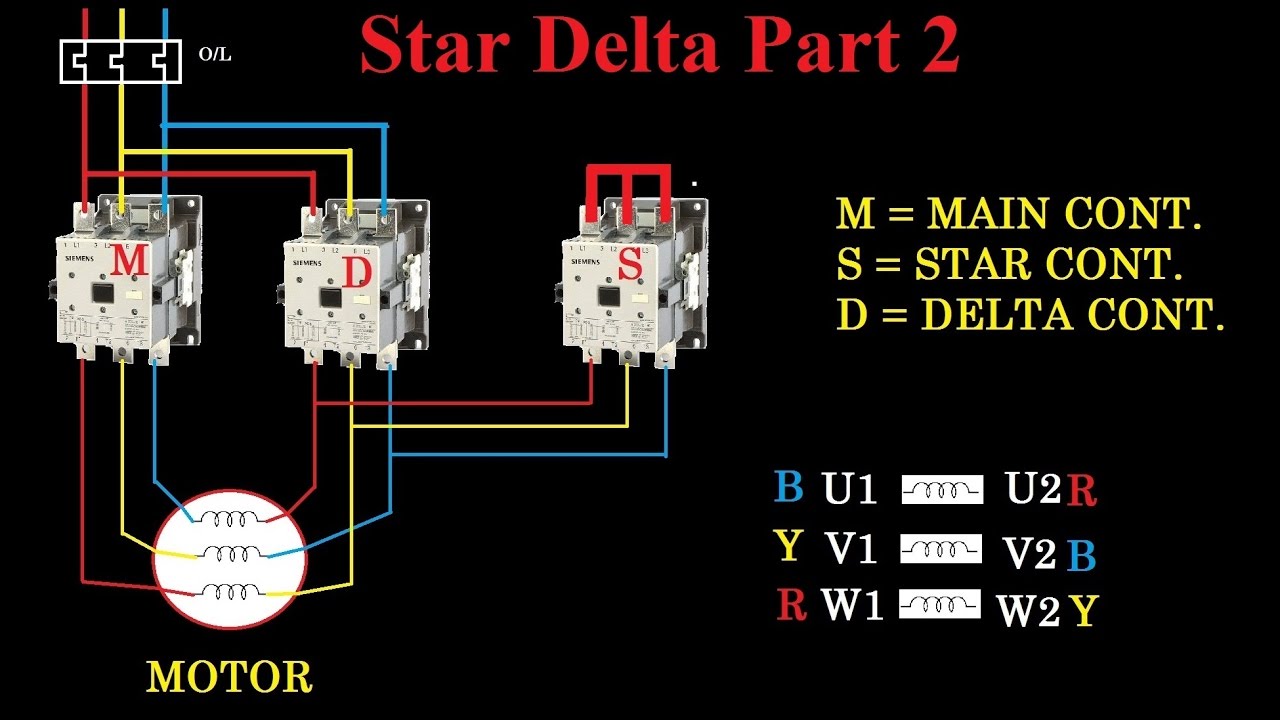

Motor Starters Star Delta Starter Y D Power Control Wiring Delta Connection Electrical Circuit Diagram Home Electrical Wiring

Induction motors are robust and reliable and are used in all industries across the globe.

. DeltaWye motors DY are wound with two distinct voltage connections in mind. A single-voltage wye-delta motor typically has six leads that are marked T-1 through T-6. You switch from wye to delta after 25 to 4 seconds but the switch is instantaneous.

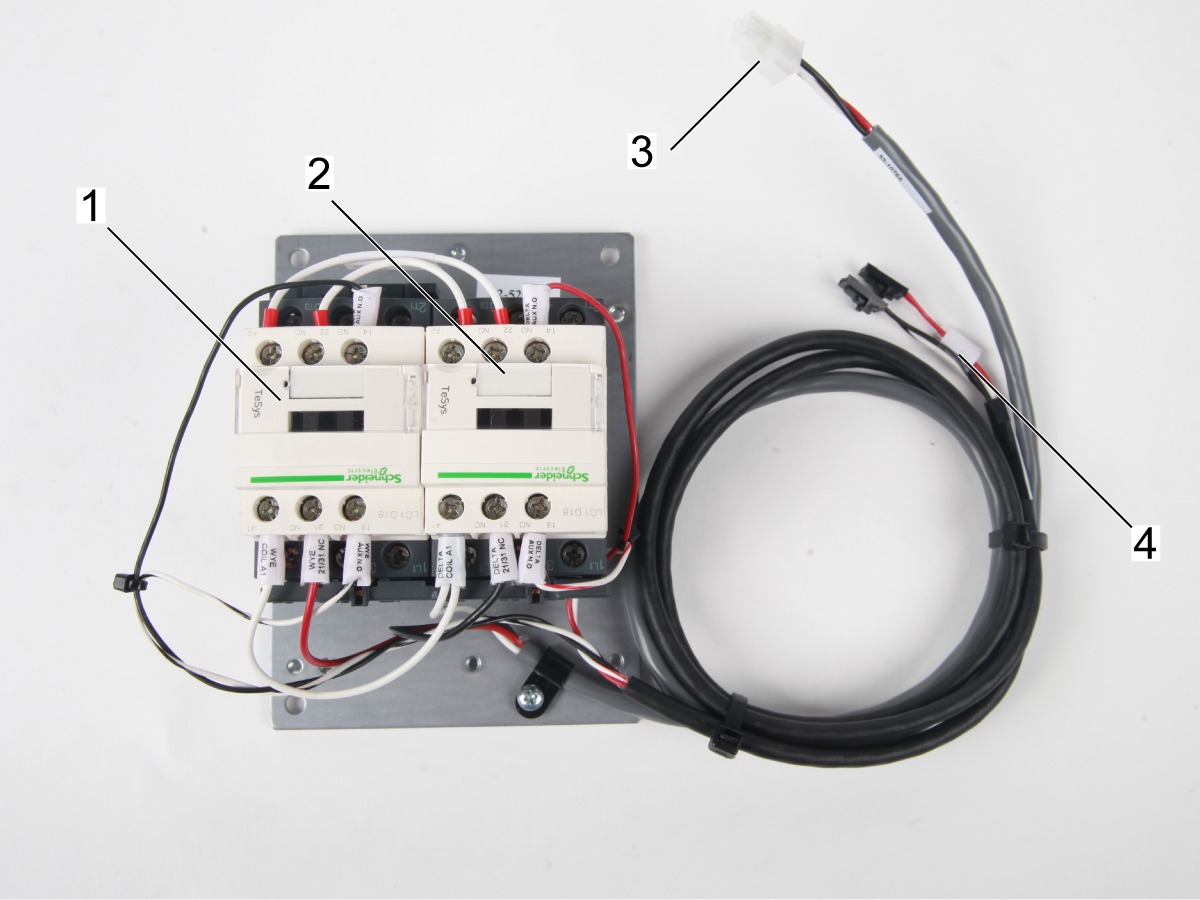

Where Isc starting phase current delta Ifl Full load phase current delta sfl slip at full load. When starters are provided with a fused controlled trans former Form F4T only the coil of the timing relay is operated from the secondary of that transformer. There is a loose connection on the WYEDELTA buss connectors.

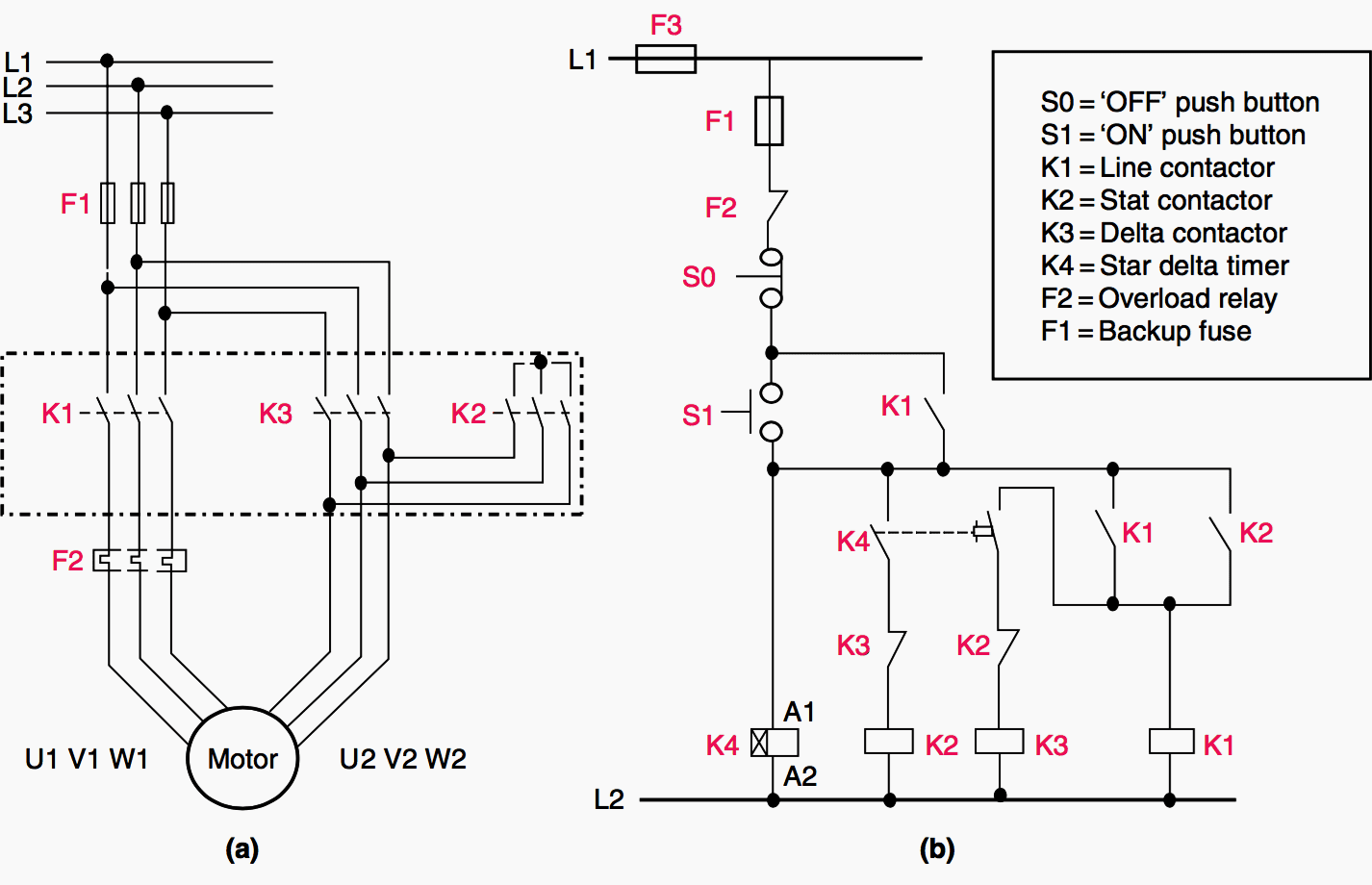

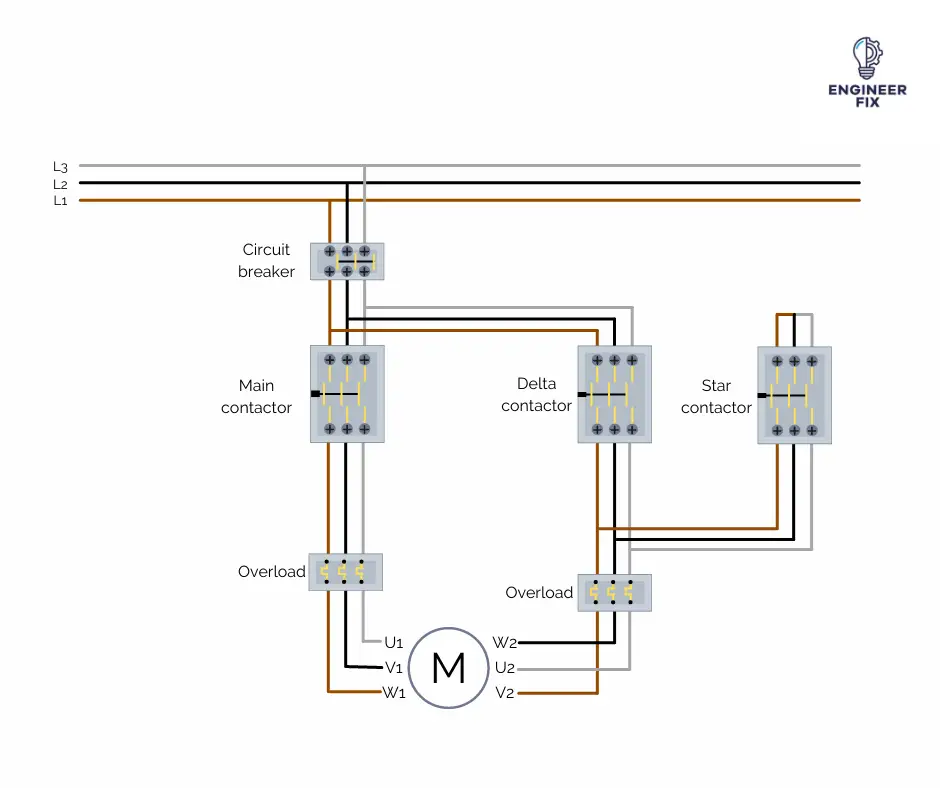

Various methods are followed to start induction motors out of which star-delta starters are the most commonly used ones to reduce the starting current. View Wye-Delta and Solid State Starter Application Guide for more information and detail on wye-delta starting. It is thus seen that star delta starting reduces the starting torque to one third that obtainable by direct delta starting and also the starting line current to one-third.

This is a very well known problem with Open Transition Wye-Delta starting. The initial connection should be in the star pattern that results in a. This method is actually reduced voltage but is accomplished by changing the motor phase connections such that a winding that is designed to run with phase voltage equal to line voltage on delta connection is wye connected for starting to put less than line voltage on each phase.

It is the so-called open transition wye-delta starter thats the culprit. We stock hundreds of complete Trane Cutler-Hammer starters and contactors used in chiller wye-delta configurations. It has to do with the phase shift that takes place when switching from Wye to Delta and how that interacts with any residual magnetism in the motor at that moment and the point in the sine wave at that moment etc.

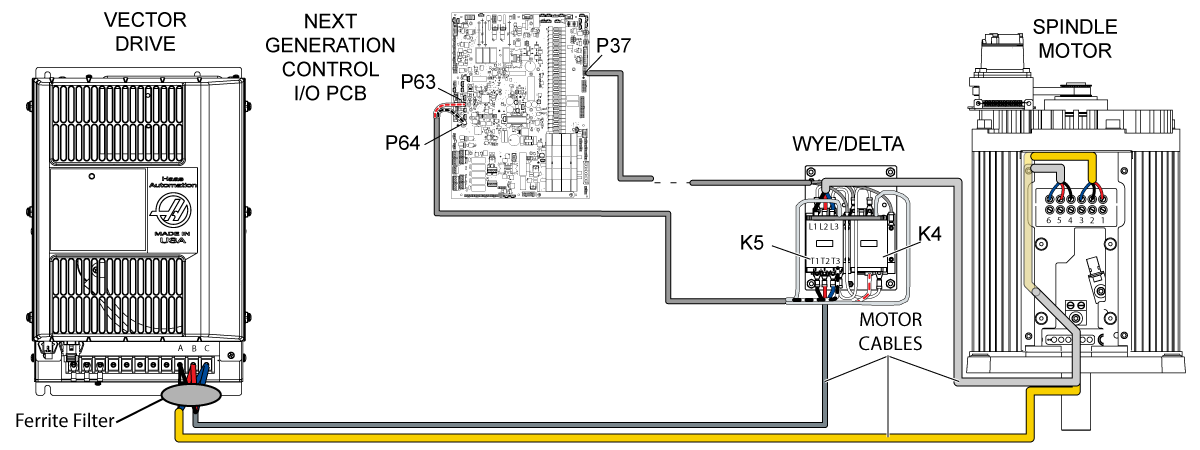

For dual-voltage motors the wye-delta motor Starting Voltage Reduction 480V 3----- 480 173----- 1 173 x 480 0577 x 480 277V. The counter emf should have been reduced. 38 Figure 31 Wye-Delta Starter.

In addition the form factor is typically much smaller with a soft starter than that of an electro-mechanical. Increase your startrun timer to around 10 seconds use a ammeter to check you motor. There is an open coil on one of the Wye-Delta contactors.

Once the motor runs at full speed in wye disconnect the power to the wye contactor coil let the speed fall to half and then connect power to the coil of the delta contactor. Check the Wye-Delta connections for arching or burn marks. Effectively the voltage is reduced by 1732.

Wye Start Delta Run. Make sure the connections are tight. Published September 19 2016.

Moment to limit inrush then close another contact for full voltage you could say they are more related to auto transformer starters than y-delta. Some wye-delta starters for large motors can cause peak currents in the power system to exceed the normal trip settings of branch circuit breakers. This video covers the basics of a wye-delta motor starterFor other videos on reduced voltage starting methodsPart-winding starter.

Class 9999 Type SF4 fuse block kit. 39 Figure 32 Wye-Delta Starter Connection to Twelve-Lead Motor at 240V Three-Phase. Star-delta starters are cheaper than soft-starters and are widely seen in small scale.

Star-delta starter Wye-Delta Starters Circuit working. For dual-voltage motors the wye-delta motor Starting Voltage Reduction 480V 3----- 480 173----- 1 173 x 480 0577 x 480 277V. Rockwell Automation provides soft starters capable of direct wiring up to wye-delta motors.

Class 9070Type K50 control transformer. If the delta contactor closes before the wye contactor has cleared the arc contact damage is the obvious result. Spindle load pegs to 200.

I did a 150Hp 415V 6 Wire 3 Phase Star Delta Grasso 6 Cylinder reciprocating refrigeration compressor about 8 years ago and this had a 20 seconds star WYE time before changeover to Delta. Starters are different in that they use Res. Closed transition starters do not permit this peak to occur.

Starting the Wye Delta. This would require another timer. 38 Figure 31 Wye-Delta Starter Connection to Twelve-Lead Motor at 480V Three-Phase.

Inspect the WYEDELTA contactor buss connections make sure they are making all the terminal leads. Because this sort of winding is often supplied by European motor manufacturers the stators are frequently rated for 50Hz however 60Hz varieties do exist. This is a very well known problem with Open Transition Wye-Delta starting.

Hence Ts starTfl IscIfl2sfl3. Both types are diagrammed in accompanying illustrations. Applications with a load torque higher than 50 of the motor rated torque will not be able to start using the start-delta starter.

Now i thought that primary resistance starting and a wye-delta starter were two different animals. After a period of time adjusted by - timer current sensor etc or when the motor reaches approximately 80 full speed contactor 2M 2S are energized connecting the motor in a delta configuration. Other coils operate at line voltage.

In addition to complete units we also have all renewal parts for these starters including auxiliaries coils contact kits and interlocks. There are numerous papers written about this available on the. The star-delta wye-delta starting method controls whether the lead connections from the motor are configured in a star or delta electrical connection.

The motor may be connected for either 230V or 400V depending on the installation voltage. For all devices ordered with form F4T the following are used. A malfunctioning transition timer can cause excessive current when the delta contactor closes.

Figure 30 European Version of an Open-Transition Wye-Delta Motor Starter - Power. In comparison a standard single-voltage delta motor has three leads that are marked T-1 through T-3.

Motor Problem In Star Delta Starter In Air Compressor Electrical Engineering Stack Exchange

Star Delta Motor Starting Performance

Star Delta Starter Plc Program And Wiring Part 5

How To Troubleshoot 3 Phase Induction Motor Step By Step Guide Engineer S Portal

Star Delta With Reverse Forward Motor Starter Wiring Star Delta Starter Youtube

Star Delta Motor Starter Explained In Details Eep

Star Delta Starter Explained Working Principle Youtube

What Are The Problems When A Motor Is Running In Star But When It Goes To Delta It Automatically Stops Quora

Wye Delta Contactor Troubleshooting Guide Chc

Star Delta Motor Starter Troubleshooting

How To Troubleshoot 3 Phase Induction Motor Step By Step Guide Engineer S Portal

Automatic Star Delta Starter Control Circuit Diagram With Timer

Troubleshooting Three Basic Hardwired Control Circuits Used In Starting Electric Motor Eep

Wye Delta Contactor Troubleshooting Guide Ngc

Star Delta Starter Circuit Y D How To Wire Pros And Cons

Star Delta Starter Part 2 Youtube

Star Delta Starter Theory And Working With Power And Control Circuit Electrical Technology All About Electrical Engineering

Wye Delta Reduce Voltage Starter Electrical Motor Control Wirings

Power Circuit Of Wye Y Delta D Starter Electrical And Electronics Technology Degree